Examples

This part of the documentation describes the examples that are found in the

examples in the

repository. Akantu’s example are separated in 2 types, the C++ and the python

ones, respectively in the 2 sub-folders c++/ and python/. The structure of

this documentation follows the folder structure of the examples folder.

The examples can be compiled by setting the option AKANTU_EXAMPLES in the

cmake configuration. They can be executed from after compilation from the

examples folder in the build directory. Even though the python examples do not

need to be compiled, some file may still be generated it is then easier to run

them from the build directory. In order to set the different environment

variables needed a script akantu_environment.sh can be found in the build

directory.

If you installed Akantu from a binary packages (e.g. via pip) you can

download a tarball with all the necessary files to run the python examples from

here akantu-python-examples.tgz.

Examples in both 2D and 3D are presented with the dimension is specified in the respective example titles. The only distinctions between a 2D and a 3D simulation lie in the mesh declaration. In C++:

const Int spatial_dimension = 2; // or 3 for 3D

Mesh mesh(spatial_dimension);

mesh.read("example_mesh.msh");

In Python:

spatial_dimension = 2 # or 3 for 3D

mesh = aka.Mesh(spatial_dimension)

mesh.read("example_mesh.msh")

where example_mesh.msh is either a 2D or a 3D mesh.

C++ Examples

Solid Mechanics Model

explicit (3D)

- Sources:

- Location:

examples/c++/solid_mechanics_model/explicit

In explicit, an example of a 3D dynamic solution with an explicit time integration is shown.

The explicit scheme is selected using the _explicit_lumped_mass constant:

model.initFull(_analysis_method = _explicit_lumped_mass);

Note that it is also the default value, hence using model.initFull(); is equivalent.

This example models the propagation of a wave in a 3D steel beam. The beam and the applied displacement in the \(x\) direction are shown in Fig. 29.

Fig. 29 Numerical setup.

The length and height of the beam are \(L={10}\mathrm{m}\) and \(h = {1}\mathrm{m}\), respectively. The material is linear elastic, homogeneous and isotropic (density: \({7800}\mathrm{kg}/\mathrm{m}^3\), Young’s modulus: \({210}\mathrm{GPa}\) and Poisson’s ratio: \(0.3\)). The imposed displacement follow a Gaussian function with a maximum amplitude of \(A = {0.01}\mathrm{m}\). The potential, kinetic and total energies are computed. The safety factor is equal to \(0.8\).

The dynamic solution is depicted in Fig. 30.

Fig. 30 Dynamic solution: lateral displacement.

implicit (2D)

- Sources:

- Location:

examples/c++/solid_mechanics_model/implicit

In implicit, an example of a dynamic solution with an implicit time integration is shown.

The implicit scheme is selected using the _implicit_dynamic constant:

model.initFull(_analysis_method = _implicit_dynamic);

This example consists of a 3D beam of \(10\mathrm{m}\times1\mathrm{m}\times1\mathrm{m}\) blocked on one side and is on a roller on the other side. A constant force of \(5\mathrm{kN}\) is applied in its middle. Fig. 31 presents the geometry of this case. The material used is a fictitious linear elastic material with a density of \(1000 \mathrm{kg/m}^3\), a Young’s Modulus of \(120 \mathrm{MPa}\) and Poisson’s ratio of \(0.3\). These values were chosen to simplify the analytical solution.

An approximation of the dynamic response of the middle point of the beam is given by:

Fig. 31 Numerical setup.

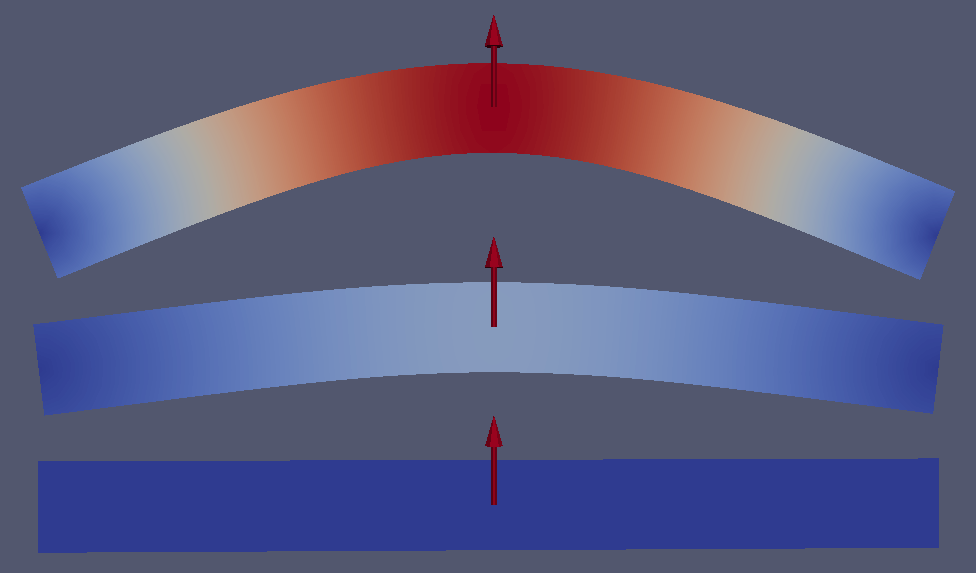

Fig. 32 presents the deformed beam at 3 different times during the simulation: time steps 0, 1000 and 2000.

Fig. 32 Deformed beam at three different times (displacement \(\times 10\)).

Static test cases (2D)

- Sources:

- Location:

examples/c++/solid_mechanics_model/static

In static, an example of how to solve a static problem is presented. The

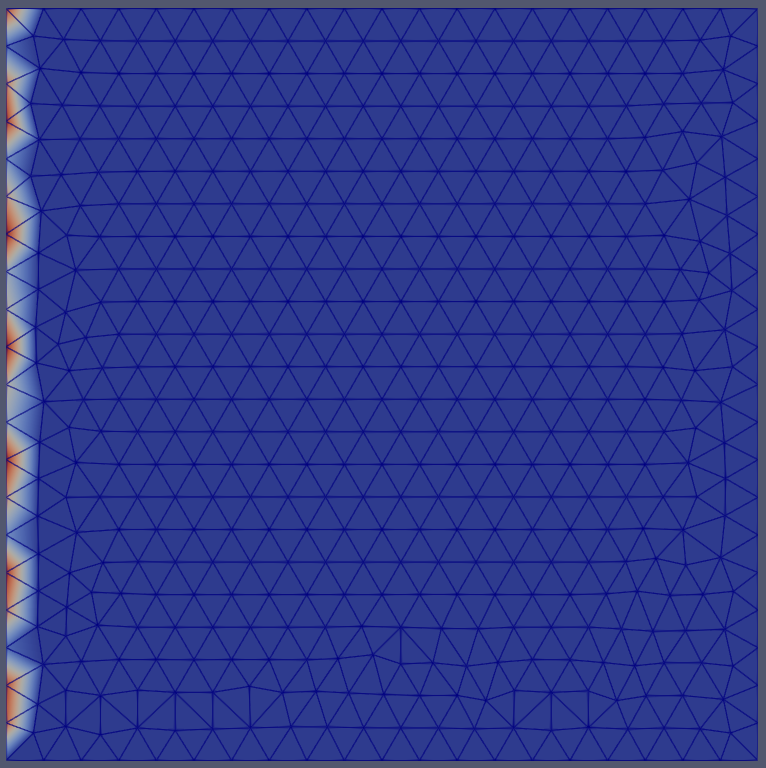

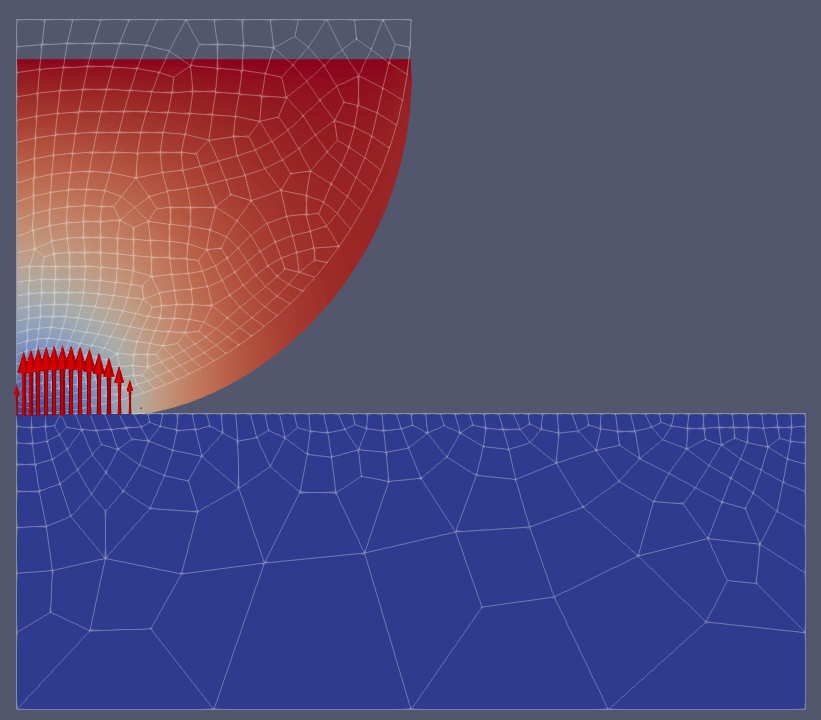

problem geometry is shown in Fig. 33. The left and bottom side

of a 2D plate are blocked with rollers and nodes from the left side are

displaced upward by \(0.01\%\) of the length of the plate.

Fig. 33 Boundary conditions for the static example.

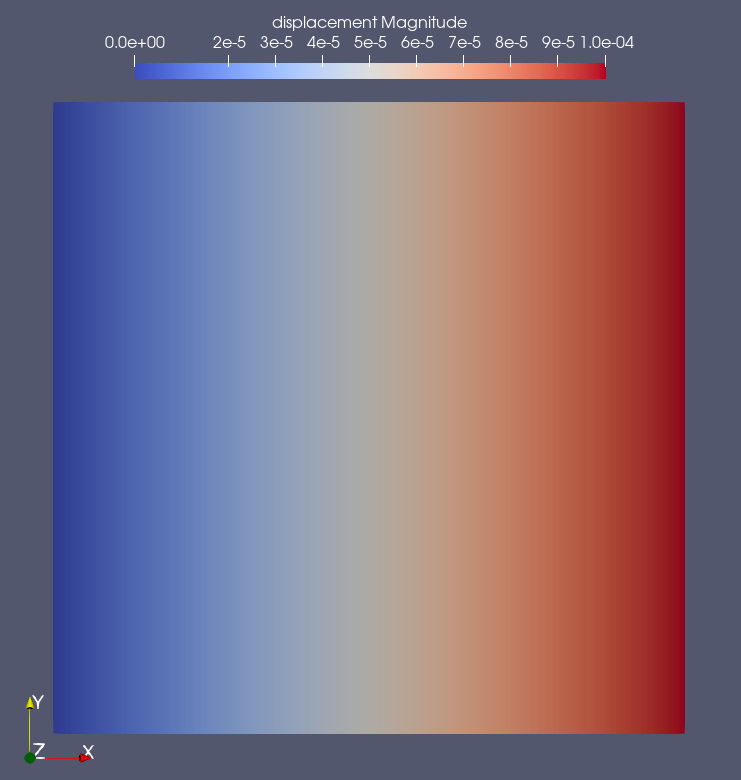

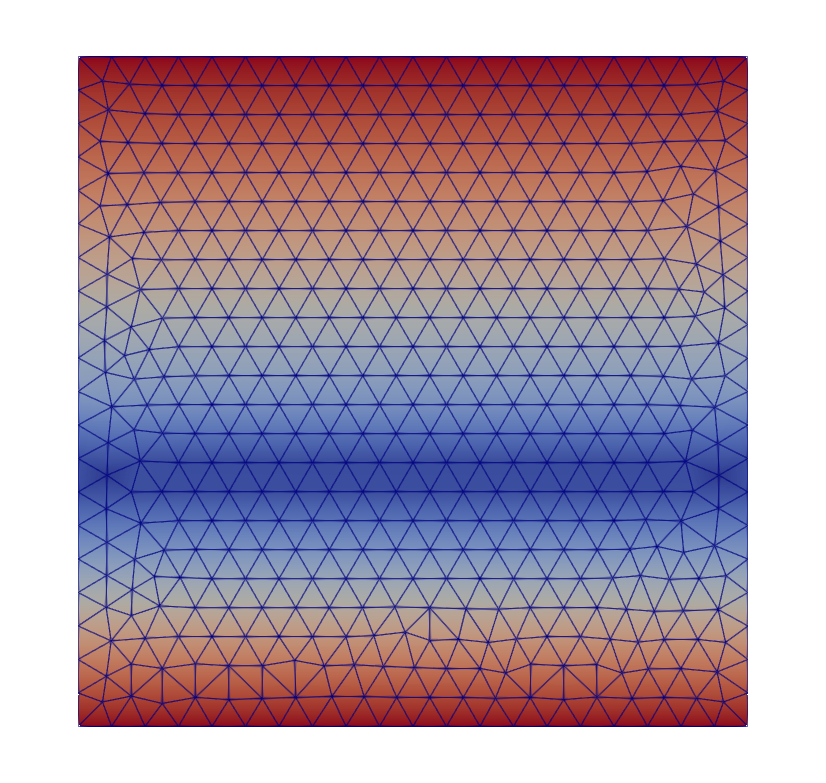

The solution for the static analysis is shown in Fig. 34.

Fig. 34 Solution of the static analysis: displacement magnitude.

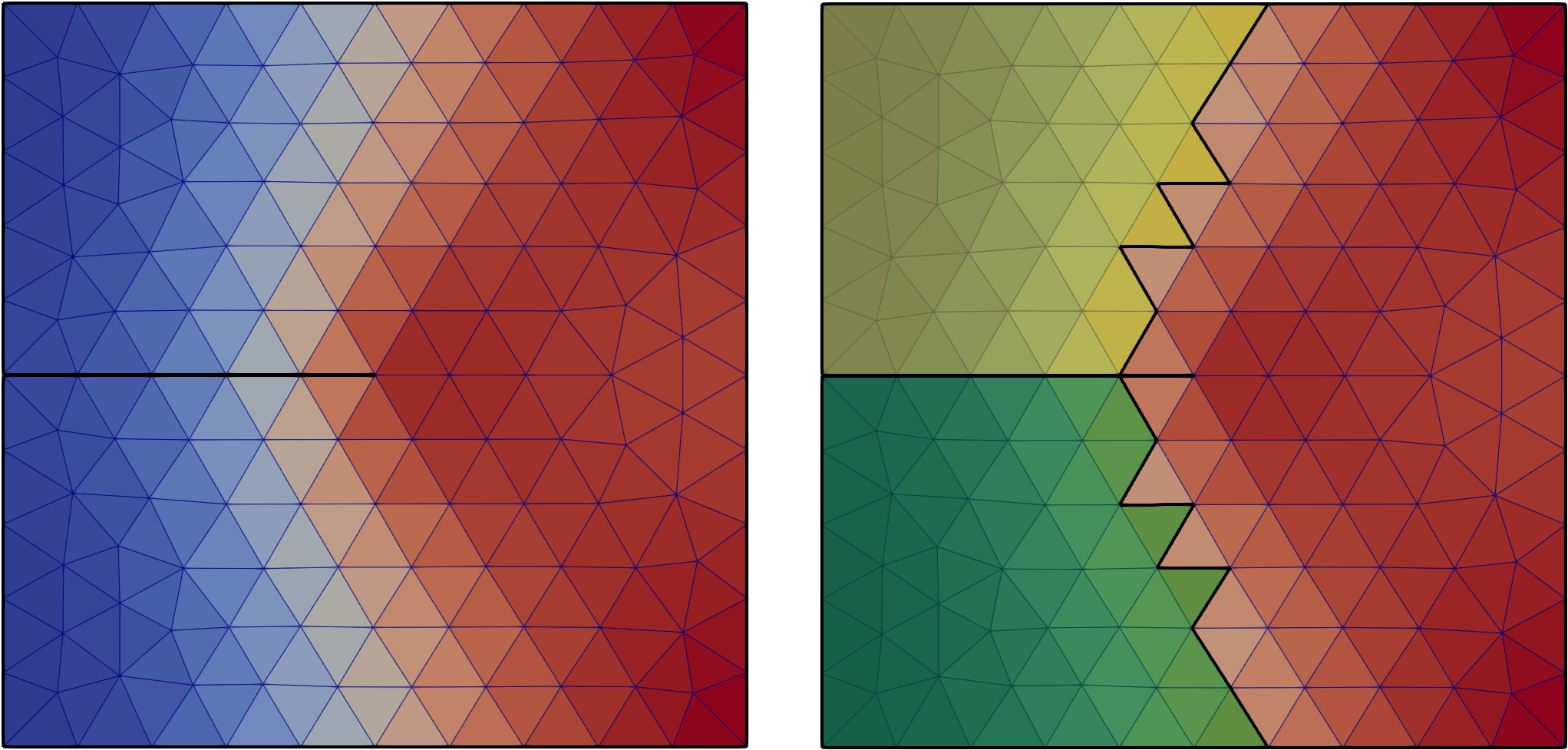

parallel (2D)

- Sources:

- Location:

examples/c++/solid_mechanics_model/parallel

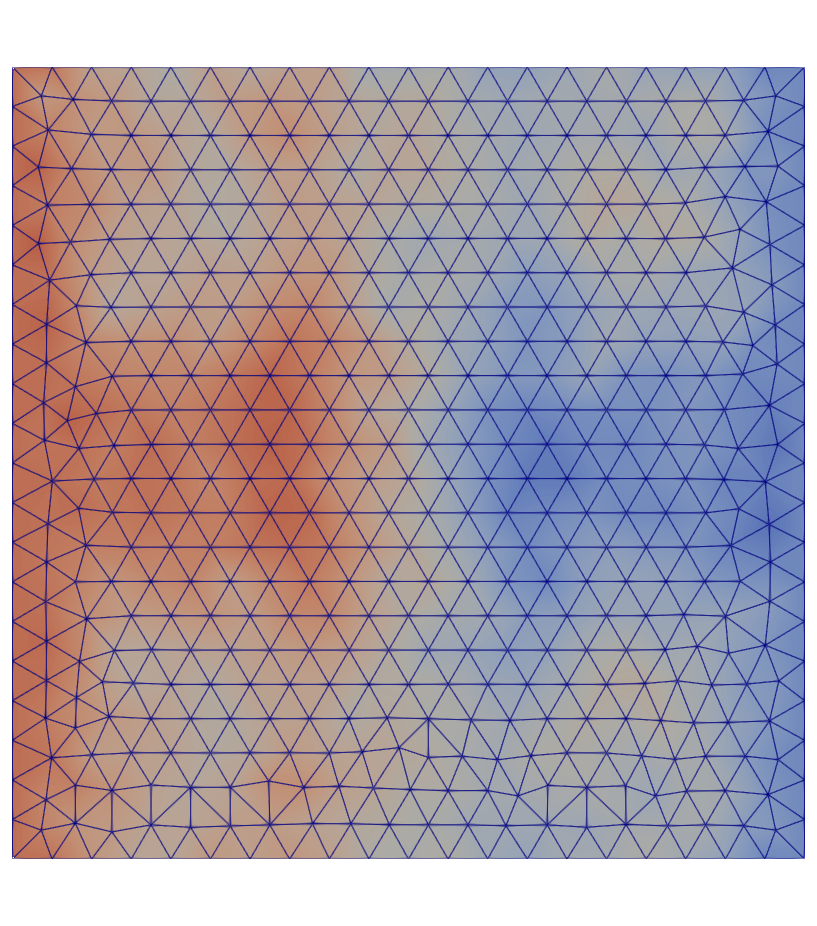

In parallel, an example of how to run a 2D parallel simulation is presented.

First, the mesh needs to be distributed among the processors. This is done with:

const auto & comm = Communicator::getStaticCommunicator();

Int prank = comm.whoAmI();

if (prank == 0) {

mesh.read("square_2d.msh");

}

mesh.distribute();

Here prank designate the processor rank. The mesh is read only by processor 0 and then distributed among all the processors.

All the prints are done only by processor 0. For instance:

if (prank == 0) {

std::cout << model.getMaterial(0) << std::endl;

}

Fig. 35 Displacement in the x direction.

Boundary conditions usage (2D)

- Sources:

- Location:

examples/c++/solid_mechanics_model/boundary_conditions

In predefined_bc it is shown how to impose Dirichlet boundary condition

using the predefined BC::Dirichlet::FixedValue

(Fig. 36). Three built-in Dirichlet functors exist:

FixedValue, FlagOnly and IncrementValue.

Fig. 36 Dirichlet boundary conditions for the predifined_bc case.

To define another functor, a class inherited from

BC::Dirichlet::DirichletFunctor can be created as illustrated in the example

user_defined_bc where a sinusoidal BC is imposed. The corresponding

sinusoidal displacement is depicted in Fig. 37. Note

that a Neumann BC is also imposed.

Fig. 37 Displacement magnitude for the user_defined_bc example.

new_material (2D)

- Sources:

- Location:

examples/c++/solid_mechanics_model/new_material

In new_material it is shown how to use a user-defined material for the simulation. All the details are described in Adding a New Constitutive Law. The geometry solved is shown in Fig. 38.

Fig. 38 Problem geometry.

parser (2D)

- Sources:

- Location:

examples/c++/solid_mechanics_model/io/parser

In io/parser, an example illustrating how to parse an input file with user-defined parameters is shown. As before, the text input file of the simulation is precised using the method initialize. In the input file, additionally to the usual material elastic section, there is a section user parameters with extra user-defined parameters.

Within the main function, those parameters are retrived with:

const ParserSection & usersect = getUserParser();

Real parameter_name = usersect.getParameter("parameter_name");

dumper (2D)

- Sources:

- Location:

examples/c++/solid_mechanics_model/io/dumper

In io/dumper, examples of advanced dumping are shown.

dumper_low_level aims at illustrating how to manipulate low-level methods of DumperIOHelper. The goal is to visualize a colorized moving train with Paraview.

It is shown how to dump only a part of the mesh (here the wheels) using the function createElementGroup of the mesh object:

ElementGroup & wheels_elements = mesh.createElementGroup("wheels", spatial_dimension);

One can then add an element to the group with:

wheels_elements.append(mesh.getElementGroup("lwheel_1"));

where lwheel_1 is the name of the element group in the mesh.

Fig. 39 The wheels and the full train are dumped separately.

dumpable_interface does the same as dumper_low_level but using dumpers::Dumpable which is an interface for other classes (Model, Mesh, …) to dump themselves.

Solid Mechanics Cohesive Model

Solid mechanics cohesive model examples are shown in solid_mechanics_cohesive_model. This new model is called in a very similar way as the solid mechanics model:

SolidMechanicsModelCohesive model(mesh);

Cohesive elements can be inserted intrinsically (when the mesh is generated) or extrinsically (during the simulation).

cohesive_intrinsic (2D)

- Sources:

- Location:

examples/c++/solid_mechanics_cohesive_model/cohesive_intrinsic

In cohesive_intrinsic, an example of intrinsic cohesive elements is shown.

An intrinsic simulation is initialized by setting the _is_extrinsic argument of model.initFull to false:

model.initFull(_analysis_method = _explicit_lumped_mass, _is_extrinsic = false);

The cohesive elements are inserted between \(x = -0.26\) and \(x =

-0.24\) before the start of the simulation with

model.getElementInserter().setLimit(_x, -0.26, -0.24);. Elements to the

right of this limit are moved to the right. The resulting displacement is shown

in Fig. 40.

With intrinsic cohesive elements, a bi-linear or exponential cohesive law should

be used instead of a linear one (see section

Intrinsic approach). This is set in the file material.dat:

material cohesive_bilinear [

name = cohesive

sigma_c = 1

beta = 1.5

G_c = 1

delta_0 = 0.1

penalty = 1e10

]

Fig. 40 Displacement in the x direction for the cohesive_intrinsic example.

cohesive_extrinsic (2D)

- Sources:

- Location:

examples/c++/solid_mechanics_cohesive_model/cohesive_extrinsic

In cohesive_extrinsic, an example of extrinsic cohesive elements is shown.

An extrinsic simulation is initialized by setting _is_extrinsic argument of model.initFull to true:

model.initFull(_analysis_method = _explicit_lumped_mass, _is_extrinsic = true);

Cohesive elements are inserted during the simulation but at a location restricted with:

CohesiveElementInserter & inserter = model.getElementInserter();

inserter.setLimit(_y, 0.30, 0.20);

model.updateAutomaticInsertion();

During the simulation, stress has to be checked in order to insert cohesive elements where the stress criterion is reached. This check is performed by calling the method checkCohesiveStress before each step resolution:

model.checkCohesiveStress();

model.solveStep();

For this specific example, a displacement is imposed based on the elements location. The corresponding displacements is shown in Fig. 41.

Fig. 41 Displacement in the y direction for the cohesive_extrinsic example.

cohesive_extrinsic_ig_tg (2D)

- Sources:

- Location:

examples/c++/solid_mechanics_cohesive_model/cohesive_extrinsic_ig_tg

In cohesive_extrinsic_ig_tg, the insertion of cohesive element is not

limited to a given location. Rather, elements at the boundaries of the block and

those on the inside have a different critical stress sigma_c. This is done

by defining two different materials in the examples/c++/solid_mechanics_cohesive_model/cohesive_extrinsic_ig_tg/material.dat.

In this case the cohesive materials are chosen based on the bulk element on both

side. This is achieved by defining MaterialCohesiveRules

The four block sides are then moved outwards. The resulting displacement is shown in Fig. 42.

Fig. 42 Displacement magnitude for the cohesive_extrinsic_ig_tg example.

Contact mechanics model (2D)

- Sources:

- Location:

examples/c++/contact_mechanics_model

contact_explicit_static and contact_explicit_dynamic are solving a 2D Hertz contact patch test using the CouplerSolidContact.

The two examples follow what is described extensively in section Coupling with SolidMechanicsModel. The only main difference between contact_explicit_static and contact_explicit_dynamic is the solver used:

// for contact_explicit_static

coupler.initFull(_analysis_method = _static);

// for contact_explicit_dynamic

coupler.initFull(_analysis_method = _explicit_lumped_mass);

The material.dat file contain a contact_detector and a contact_resolution penalty_linear section as explains in section Contact detection.

Diffusion Model (2D and 3D)

- Sources:

- Location:

examples/c++/diffusion_model

In diffusion_model, examples of the HeatTransferModel are presented.

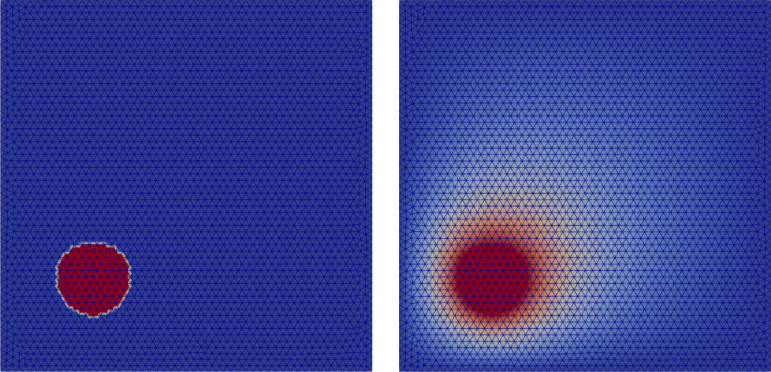

An example of a static heat propagation is presented in

heat_diffusion_static_2d.cc. This example consists of a square 2D plate of

\(1 \text{m}^2\) having an initial temperature of \(100 \text{K}\)

everywhere but a non centered hot point maintained at

\(300 \text{K}\). Fig. 43 presents the geometry

of this case (left) and the results (right). The material used is a linear

fictitious elastic material with a density of \(8940 \text{kg}/\text{m}^3\),

a conductivity of \(401 \text{W}/\text{m}/\text{K}\) and a specific heat

capacity of \(385 \text{J}/\text{K}/\text{kg}\).

The simulation is set following the procedure described in Using the Heat Transfer Model

Fig. 43 Initial (left) and final (right) temperature field

- Sources:

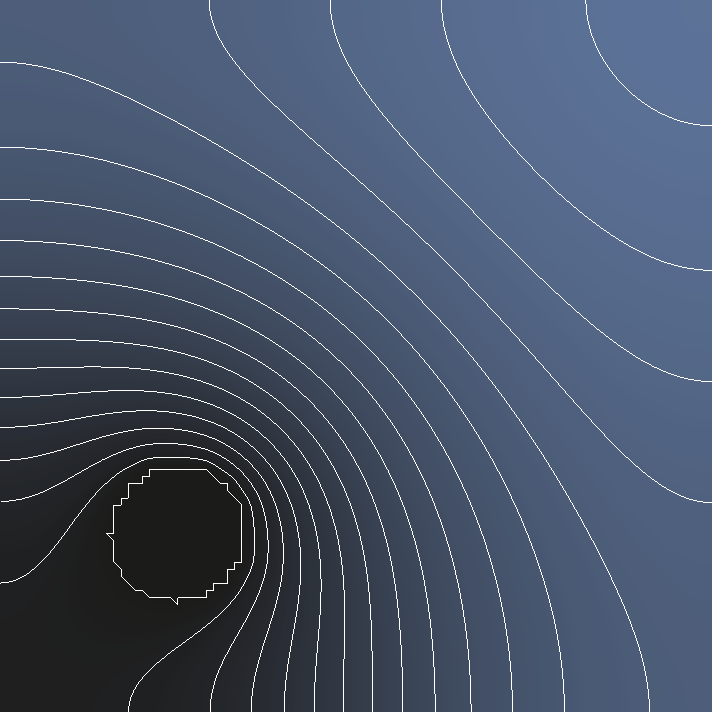

In heat_diffusion_dynamics_2d.cc, the same example is solved dynamically

using an explicit time scheme. The time step used is \(0.12 \text{s}\). The only main difference with the previous example lies in the model initiation:

model.initFull(_analysis_method = _explicit_lumped_mass);

Fig. 44 Temperature field after 15000 time steps = 30 minutes. The lines represent iso-surfaces.

- Sources:

In heat_diffusion_dynamics_3d.cc, a 3D explicit dynamic heat propagation

problem is solved. It consists of a cube having an initial temperature of

\(100 \text{K}\) everywhere but a centered sphere maintained at

\(300 \text{K}\).

The simulation is set exactly as heat_diffusion_dynamics_2d.cc except that the mesh is now a 3D mesh and that the heat source has a third coordinate and is placed at the cube center.

The mesh is initialized with:

Int spatial_dimension = 3;

Mesh mesh(spatial_dimension);

mesh.read("cube.msh");

Fig. 45 presents the resulting temperature field evolution.

Fig. 45 Temperature field evolution.

Phase-field model (2D) [Unstable]

static

- Sources:

- Location:

examples/c++/phase_field_model

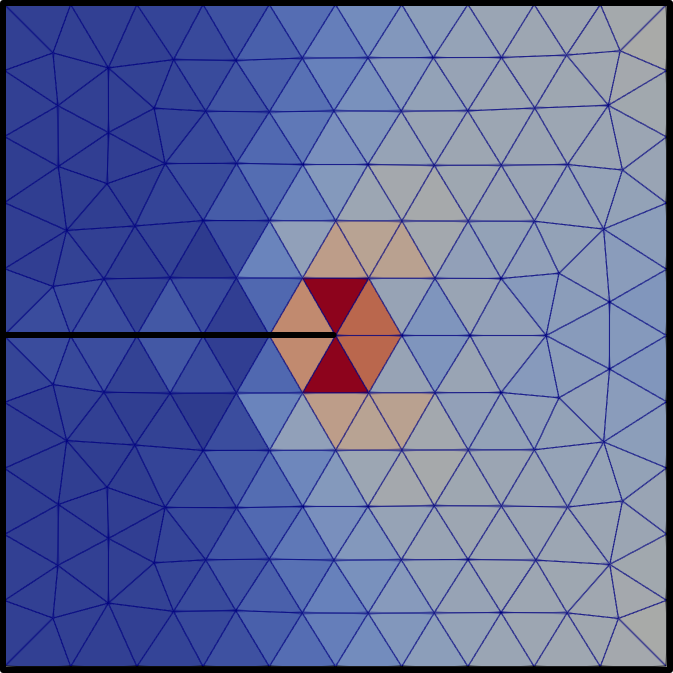

phase_field_notch.cc shows hot to set a quasi-static fracture simulation with phase-field. The geometry of the solid is a square plate with a notch. The loading is an imposed displacement at the top of the plate (mode I).

Fig. 46 Notched plate with boundary conditions and imposed displacement.

In addition, this example shows how to extract clusters delimited by the mesh boundaries and elements with damage values beyond a threshold. This can be useful to extract fragments after crack propagation.

Fig. 47 Damage field after a few iterations and two clusters (fragments) extracted.

Scalability test (3D)

- Sources:

- Location:

examples/c++/scalability_testThis example is used to do scalability test, with elastic material or cohesive elements inserted on the fly. The cube.geo should generate a mesh with roughly 4’500’000 elements and 730’000 nodes. The cube.msh file included is a tiny cube only to test if the code works.

To run the full simulation the full mesh has to be generated gmsh -3 cube.geo -o cube.msh

The simulation consist of a cube with a compressive force on top and a shear force on four sides as shown in the figure bellow

This examples was used to run the scalability test from the JOSS paper the full mesh and results presented in the following graph can be found here: perf-test-akantu-cohesive

Python examples

To run simulations in Python using Akantu, you first need to import the module:

import akantu as aka

The functions in Python are mostly the same as in C++.

The initiation differs. While in C++ a function is initialized using initialize("material.dat", argc, argv);, in Python you should do:

aka.parseInput('material.dat')

The creation and loading of the mesh is done with:

mesh = aka.Mesh(spatial_dimension)

mesh.read('mesh.msh')

Solid Mechanics Model

The Solid Mechanics Model is initialized with:

model = aka.SolidMechanicsModel(mesh)

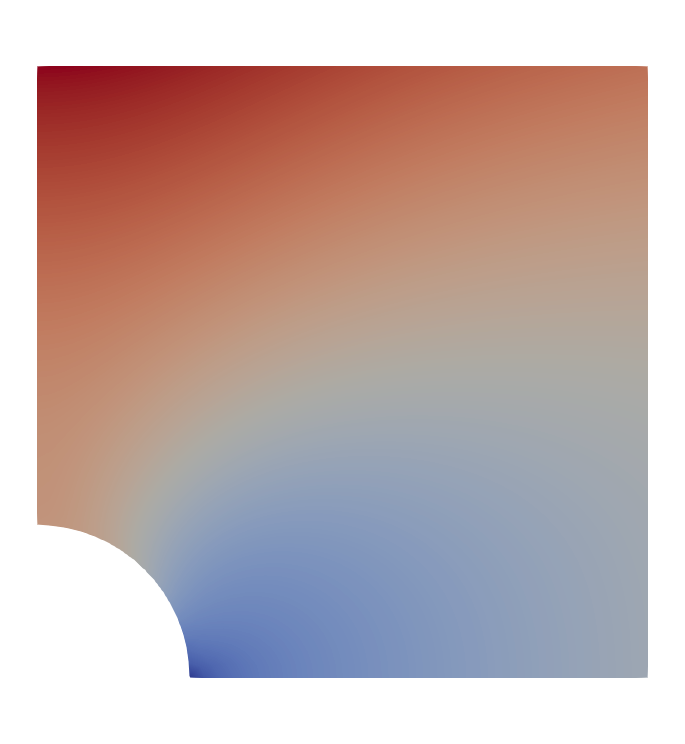

plate_hole (2D)

- Sources:

- Location:

examples/python/solid_mechanics_model/plate-hole

In plate_hole, an example of a static solution of a loaded plate with a hole. Because of the symmetries, only a quarter of the problem is modeled. The corresponding domain and boundary conditions is shown in Fig. 48.

The static solver is initialized with:

model.initFull(_analysis_method=aka._static)

Boundary conditions are applied with:

model.applyBC(aka.FixedValue(0.0, aka._x), "XBlocked")

model.applyBC(aka.FixedValue(0.0, aka._y), "YBlocked")

model.applyBC(aka.FromTraction(trac), "Traction")

where trac is a numpy array of size spatial_dimension.

Additionally, the simulation can be run in parallel. To do so, the following lines are added:

try:

from mpi4py import MPI

comm = MPI.COMM_WORLD

prank = comm.Get_rank()

except ImportError:

prank = 0

Similarly to C++, the mesh has to be distributed between the processors with:

mesh.distribute()

Fig. 48 Plate with a hole geometry.

The displacement magnitude is displayed in Fig. 49.

Fig. 49 Displacement magnitude.

dynamics (2D)

- Sources:

- Location:

examples/python/solid_mechanics_model/dynamics

In dynamics, an example of a dynamic simulation solved with an explicit time intergration is shown. This examples

model the propagation of a wave in a bar. The geometry is depicted in Fig. 50. A pulse is impose

as an initial displacement over the bar. Results are depicted in Fig. 51.

The explicit time integration scheme is set with:

model.initFull(_analysis_method=aka._explicit_lumped_mass)

This example shows how to create a new functor to set the boundary conditions. This is done by creating a class that inherits from aka.FixedValue (MyFixedValue(aka.FixedValue) in this case).

The boundary conditions are then applied with:

model.applyBC(MyFixedValue(0, aka._x), "XBlocked")

model.applyBC(MyFixedValue(0, aka._y), "YBlocked")

Fig. 50 Plate with a hole geometry.

Fig. 51 Displacement magnitude.

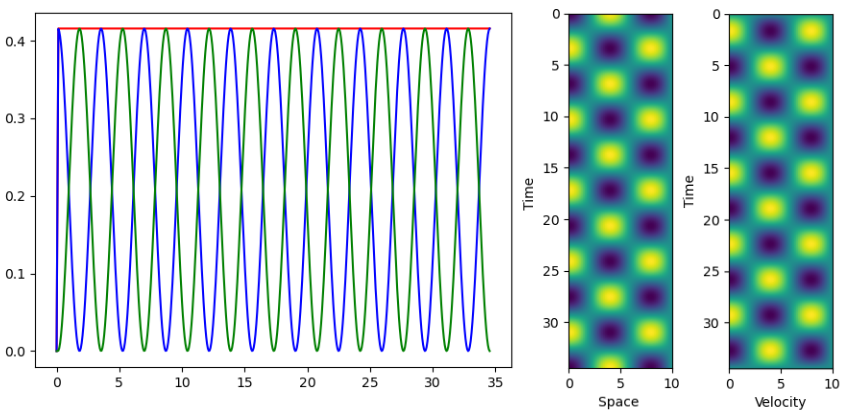

eigen_modes (2D)

- Sources:

- Location:

examples/python/solid_mechanics_model/eigen_modes

In eigen_modes it is shown how to compute the eigen modes using the library scipy.sparse. The mode can be specify with the -m argument. Simulation is performed on a bar where a pulse is imposed.

The -p argument will plot the following figures Fig. 52:

Fig. 52 Energy norms as a fonction of time (left), space-time diagram for diplacements (center) and space-time diagram for velocities (right) with the default values.

- An implicit time integration scheme is used and set with::

model.initFull(aka._implicit_dynamic)

custom-material (2D)

- Sources:

- Location:

examples/python/solid_mechanics_model/custom-material

In custom-material.py it is shown how to create a custom material behaviour. In this example, a linear elastic

material is recreated. It is done by creating a class that inherits from aka.Material (LocalElastic(aka.Material) in this case) and register it

to MaterialFactory:

class LocalElastic(aka.Material):

[...]

def allocator(_dim, unused, model, _id):

return LocalElastic(model, _id)

mat_factory = aka.MaterialFactory.getInstance()

mat_factory.registerAllocator("local_elastic", allocator)

Wave propagation of a pulse in a bar fixed on the top, bottom and right boundaries is simulated using an explicit scheme. Results are shown in Fig. 53.

Fig. 53 Wave propagation in a bar.

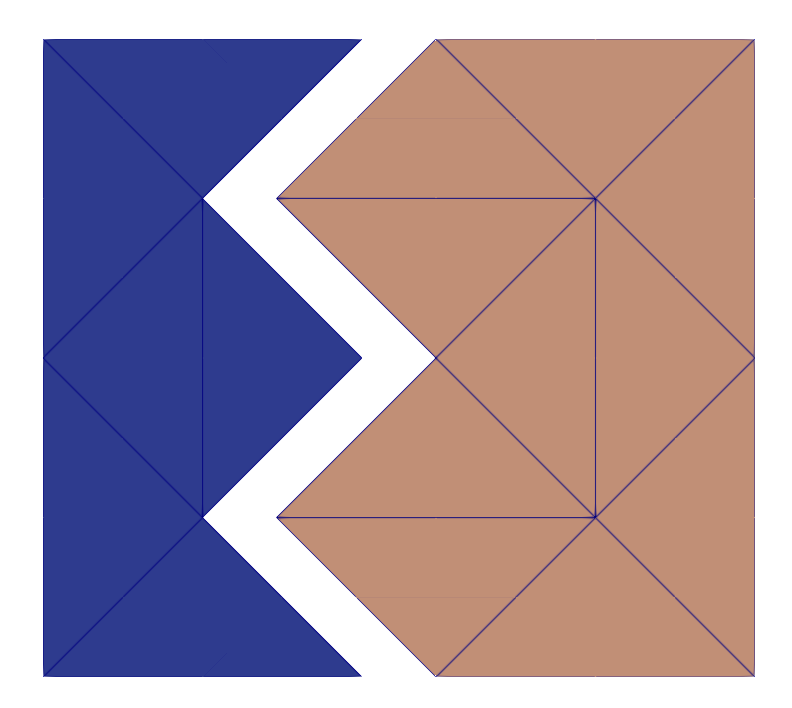

In bi-material.py, the same principle is used to create a bimaterial square. The displacement is shown in Fig. 54.

Fig. 54 Bimaterial square.

stiffness_matrix (2D)

- Sources:

- Location:

examples/python/solid_mechanics_model/stiffness_matrix

stiffness_matrixshows how to get the stiffness matrix from a mesh. It is done with::model.assembleStiffnessMatrix() K = model.getDOFManager().getMatrix(‘K’) stiff = aka.AkantuSparseMatrix(K).toarray()

solver_callback (2D)

- Sources:

- Location:

examples/python/solid_mechanics_model/solver_callback

In solver_callback, it is shown how to write a solver callback function. It is done by writing a class that inherit

from InterceptSolverCallback:

class SolverCallback(aka.InterceptSolverCallback):

[.....]

solver_callback = SolverCallback(model)

model.solveStep(solver_callback)

In that case, the solver callback is used to modify the stiffness matrix.

Solid Mechanics Cohesive Model

cohesive (2D)

- Sources:

- Location:

examples/python/solid_mechanics_cohesive_model/cohesive

In cohesive/plate.py, an example of extrinsic cohesive elements insertion is shown. This example simulates a plate

with a pre-existing crack pulled. The geometry is depicted in Fig. 55.

Fig. 55 Problem geometry.

The problem is solved statically until the onset of instability and is then solved dynamically with an explicit

integration scheme. This is done by adding a new solver with model.initNewSolver():

model = aka.SolidMechanicsModelCohesive(mesh)

model.initFull(_analysis_method=aka._static, _is_extrinsic=True)

model.initNewSolver(aka._explicit_lumped_mass)

[....]

model.solveStep("static")

[....]

model.solveStep("explicit_lumped")

The crack opening is displayed in Fig. 56.

Fig. 56 Stresses in the plate.

fragmentation (2D)

- Sources:

- Location:

examples/python/solid_mechanics_cohesive_model/fragmentation

fragmentation shows an example of a 1D bar fragmentation with extrinsic cohesive elements. It uses a custom boundary

condition to impose a constant velocity. This is done by creating a class that inherits from DirichletFunctor.

The result is shown in Fig. 57.

Fig. 57 1D bar fragmentation.

Contact mechanics model (2D)

- Sources:

- Location:

examples/python/contact_mechanics_model

In compression.py it is shown how to couple the Solid Mechanics Model with the Contact Mechanics Model. The example simulate the contact betweem two blocks.

Phase-field model (2D)

static

- Sources:

- Location:

examples/python/phase_field_model

phasefield-static.py shows how to setup a static phase-field fracture simulation. An imposed displacement is imposed on the top of a notched square plate.

Fig. 58 Notched plate with boundary conditions and imposed displacement.

In static simulations, we use loading steps to apply the displacement incrementally. At each time step, the solvers of the solid mechanics model and the phase-field model are called alternately until convergence is reached.

Fig. 59 Damage field after a few iterations.

dynamic

- Sources:

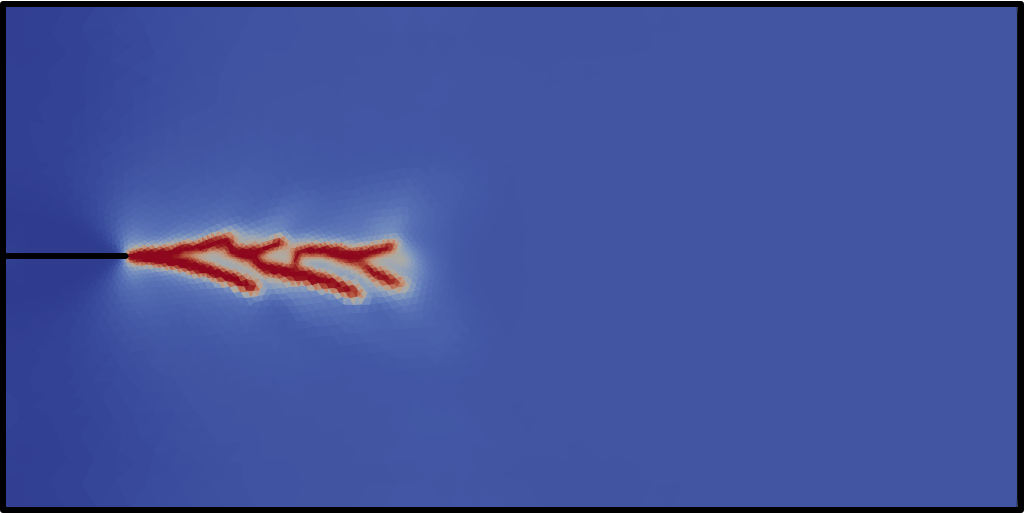

phasefield-dynamic.py shows how to setup a dynamic phase-field fracture simulation. A notched plate is pre-strained in mode I using Dirichlet BC and a static solve. The simulation is then continued in dynamic using an explicit Neumark scheme.

Fig. 60 Notched plate with boundary conditions and imposed displacement.

At each time step, each solver is called once to find the displacement field and the damage field.

Fig. 61 Crack propagation and branching.